Black oxide hex bolts

Different coating chemistries have long been used by fastener manufacturers to improve corrosion resistance, lubricity, or both. Understanding a solar fastener’s coating can ensure joint integrity, improve field life, and increase serviceability.

Black oxide is a conversion coating used on fasteners made from ferrous (iron-containing) materials, copper and copper based alloys, stainless steel, zinc and more.Black oxide is sometimes used for appearance, to minimize the reflection of light, or for mild corrosion resistance. For black oxide to achieve maximum corrosion resistance properties, it must be impregnated with wax or oil. One advantage black oxide has over other coatings is its minimal buildup. Solar assemblies commonly use black oxide to coat a stainless steel fasteners for aesthetic purposes, creating an evenly colored black finish without compromising the integrity of the fastener.

Inorganic coatings encompass anodizing, surface conversion, enameling, metallic coatings and more. Created through a chemical action that changes the surface layer of the metal into a metallic oxide film or compound, inorganic coatings are primarily used to reduce corrosion.

DURA-CON salt spray test results

In addition to the previously mentioned unbranded coatings, the Magni organization offers a selection of proprietary coatings for solar fasteners. The 565 coating from Magni allows lubricants to be integrated into the topcoat, which will typically eliminate the need for messy and cumbersome post-treatments. This non-electrolytically applied, zinc-and-aluminum-rich coating also eliminates the concern of hydrogen embrittlement. Able to be formulated in many colors, the Magni 565 coating also comes in several friction levels while still providing consistency across different bearing surfaces.

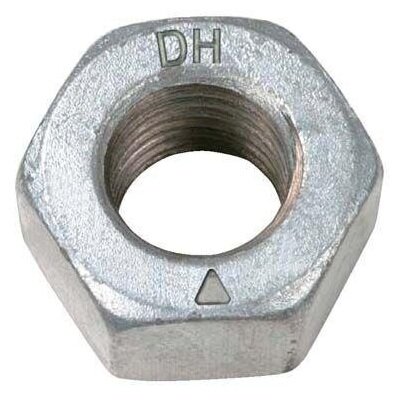

DURA-CON brand fasteners offer a variety of Grade 5 and standard steel fasteners that are coated to be suitable for use as solar fasteners. DURA-CON fasteners employ a three layer coating system consisting of an inorganic zinc-rich first coat and an aluminum-rich organic second coat. Friction modifiers are integrated into the topcoat, resulting in repeatable torque tension characteristics during assembly. Grade 5 bolts are stronger than A307 zinc, hot dip galvanized or 300 series stainless steel bolts, and DURA-CON coating provides superior corrosion resistance; easily withstanding 1500 hours of Salt Spray per ASTM B-117 with no corrosion whatsoever.

For more information about which coating type my be best for your solar fastener application, contact us today.

.png)