Cables and connectors are vital parts of a PV array. The selection of cables is an important procedure, but how the cables are managed thereafter also influences how the entire PV system will function. Poor cable management can ultimately lead to problems.

Cables were the culprits in two fires that happened in PV arrays, one in Bakersfield, California in 2008 and one in Mount Holly, North Carolina in 2011. Bill Brooks from Brooks Solar prepared a paper for the Solar America Board for Codes and Standards explaining the causes of the fires. In both cases, cable insulation damage was identified as the root cause. A significant amount of work goes into the complex process of designing and planning a PV power plant, whether on the rooftop of a building or ground-mounted on the field. This then translates into an efficient, working PV power plant in situ. With the rapid uptake of PV, it is also common to see homeowners who design and implement their own small PV rooftop projects. With so much already invested, it would be vexing if careless cable management after installation lead to losses. And dangling, untidy cables are simply unaesthetic.

Read the full story at PV Magazine

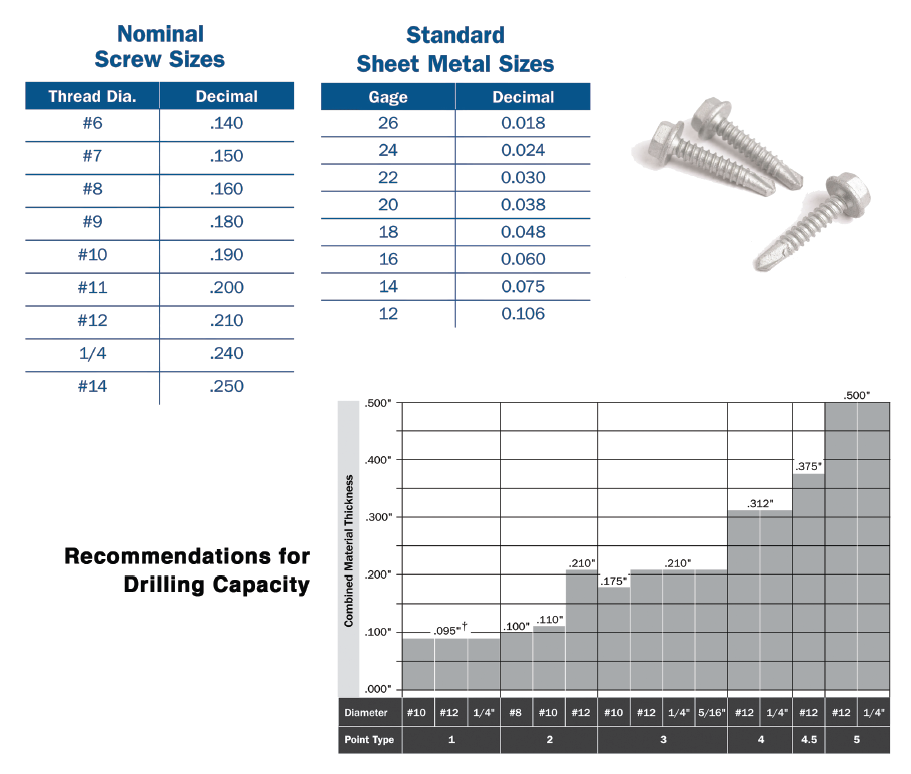

Click here to download a printable PDF version of the guide to use for reference when making decisions about which drill point size is right for which fasteners for your application.

If you have any questions about self drilling screws from China Special Fasteners, please call us at +86-755-27859830.

Zinc is naturally found in elements such as air, water, and soil as well as in plants, animals, and humans. It is the 27th most abundant element in the Earth’s crust and is infinitely recyclable without the loss of its properties, making it a true renewable resource.

Zinc’s ability to protect iron and steel products from corrosion has been known for centuries as the material has been used in construction since the second century. More than 13 million tons of zinc is produced annually worldwide—70 percent of which is from mined ores and the remaining is from recycled sources. More than half of this annual production is used in zinc coatings to protect steel from corrosion.

Click here to read the rest of the article at Construction Specifier.

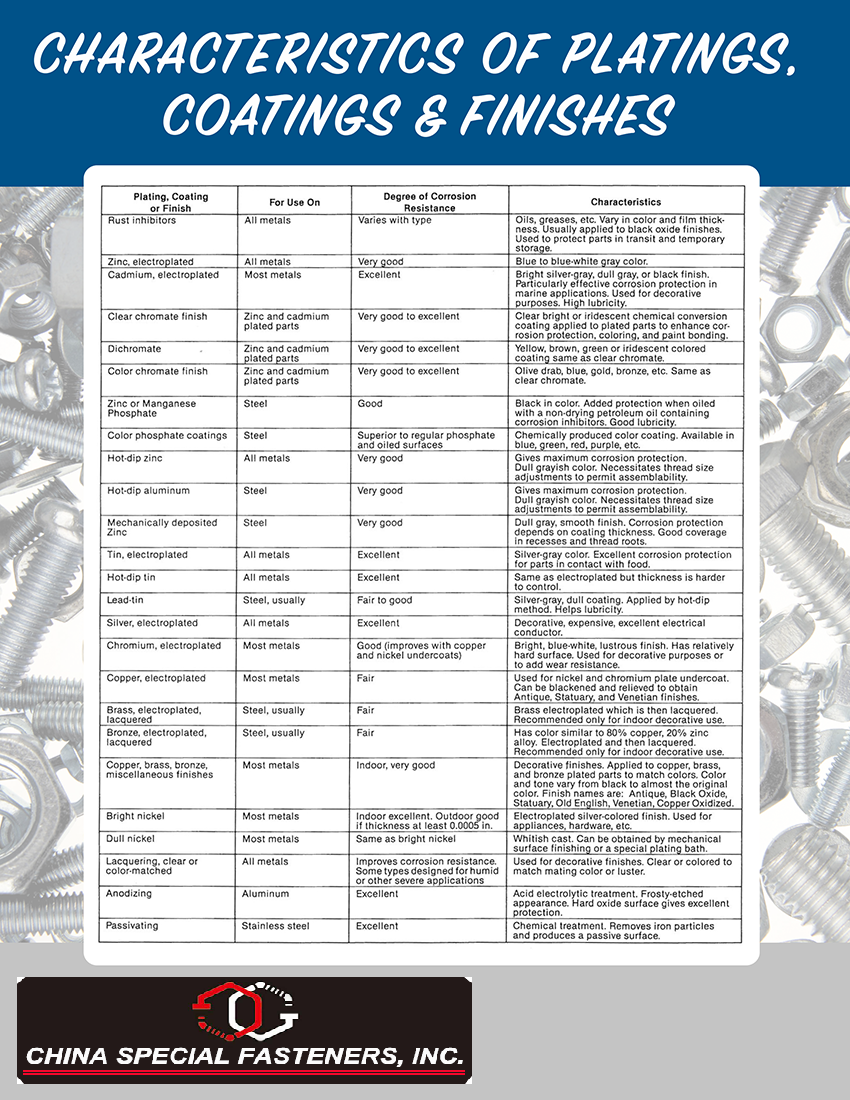

Characteristics of Platings, Coatings & Finishes Chart

While we're on the topic of platings (like zinc), we'd like to offer you our downloadable Characteristics of Platings, Coatings & Finishes chart.

Click the image to the right to download a printable PDF version of the chart to use for reference when making decisions about which plating, coating or finish you should use on fasteners for your application.

Unlike most distributors, China Special Fasteners is willing to break boxes to offer smaller quantities of Elco Construction fasteners for the convenience of our customers. No longer do you need to buy hundreds or thousands of each type of Elco fasteners, you can contact us to request a quote for just the quantities you need.

Click here to download the Elco product selection guide.

Ensuring that your employees are protected when working at heights is the business of FallTech Services Group. Fall Protection equipment will only protect a worker if they know when, where and how it is to be used. FallTech Services Group specializes in helping businesses identify fall safety hazards, write fall protection plans, engineer anchorage solutions and train employees in fall safety.

Offering a well equipped training facility with certified fall safety trainers, FSG provides a full range of in depth courses in fall protection. A balance of hands on training and classroom instruction provides the optimal fall protection training experience and course offerings ranging from entry level fall safety hazard awareness to the supervisory level competent person fall safety training. Additionally, custom fall safety courses and site specific fall protection training are available through our alternative curriculum program.

Regularly scheduled fall safety courses are available to attendees both at the FallTech Training Center in Compton, CA, a variety of regional venues throughout the United States, and at client facilities throughout North America.

FallTech Services Available

- Fall Safety Hazard Analysis

- Site Survey

- Written Job Fall Safety Analysis

- Building Plan Review

- Written Fall Protection Plans

- Jurisdictional Code Review

- Fall Safety Structural Review

- CAD Design

- Customized Fall Protection Equipment Development

- Fall Safety Anchor Point Design

Unlike most of their competitors, all FallTech products are proudly MADE IN USA.

Elco Construction recently released their new product selection guide, which clarifies what fasteners from the Flex Technology family are best for which applications.

Click here to download the selection guide, or see below for which substrate materials work best for Elco Flex Technology products.

Steel to

Steel

Dril-Flex

Bi-Flex

Tap-Flex

Steel / Aluminum Combinations

Dril-Flex

Bi-Flex

Tap-Flex

Aluminum to

Aluminum

Dril-Flex

Bi-Flex

Tap-Flex

All-Flex

Treated Wood to

Steel or Aluminum

Bi-Flex