FAST, HIGH-TORQUE, STICK-FIT

STYKFIT®7 PATENTED HIGH-SECURITY LEVEL

Protected by worldwide patents, STYKFIT®7 incorporates the best features of other drive systems to create a superior driving fastener. It indexes faster than Phillips®, torques higher than Torx®, sticks to the bit better than Robertson®(square drive); creating the highest performing fastener ever made.

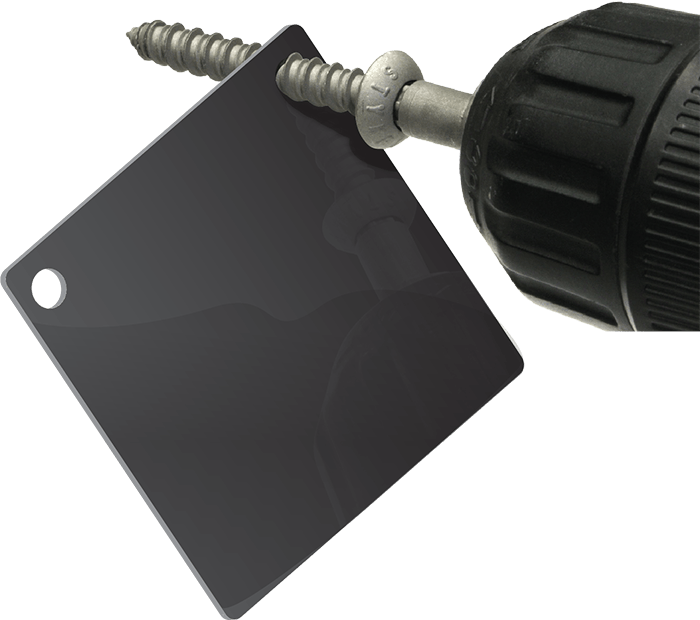

Tolerances between the screwdriver and the screw are reduced to less than .0005. This is in comparison to other fasteners that can have up to .010. This creates a near weld-like bond which allows one-handed installation, and the ability to pick up and place the assembly piece in position. Ease of use and improved installation times are the result. If you're looking to make gains in productivity and efficiency, this is it.

STYKFIT® 7 FEATURES

Secure/Tamper-proof - Unique 7-fin profile and center rejection pin

Holds fasteners tightly enough to bear weight - Driver bit holds more than the fastener alone. Tapered driver bit indexes tightly enabling screw to bear the weight of the piece being assembled.

Fast assembly time - Fast indexing, even while driver bit is rotating; no fumbling, dropping, or re-attaching

Non-magnetic - Hold fastener without need for magnetic driver bits or sliding sleeves (works with stainless and coated fasteners)

Extreme torque threshold - Higher torque allows for more security

Brykote™ Protective Coating - Up to 700 hours of extra corrosion protection. Available in a variety of colors

Made in USA - Engineered and crafted 100% in the USA

Guaranteed - More secure and faster assembly guaranteed - wait until you see how efficient you can be

TORQUE LIKE NO OTHER

Torque is another advantage. At present the highest torquing systems use lobe designs with multiple straight walls. Unfortunately, these installation bits have tolerances that intersect approximately 15% of the side walls. This creates stress “cam-out” points and reduces the torque that can be applied. STYKFIT®7 drive systems allow for over 98% contact of bit-to-screw. This tight grip spreads the load over the entire driver, eliminating fracture points and providing higher torque.

QUICK INDEXING

Indexing features make this fastener usable by robots. STYKFIT®7 employs a rounded counterbore system in the head of the screw which guides a spinning driver bit into the socket. This oversized counterbore means the bit can miss the socket by over .020 and still be directed into the fastener keyway.

All told, these features combine to create the most advanced, user-friendly fastener ever designed. Screws are often incorrectly purchased based on their price. The real cost of the fastener is in installation. The auto industry once calculated installation costs (on an assembly line) were over $0.25 each. This likely has ballooned to over $1.00 each. A poorly placed or torqued fastener is one of the leading reasons for customer complaints. Therefore, technologies to lessen those problems are the most cost effective solutions. STYKFIT®7 fasteners are invented, designed, and manufactured in the United States.

STOPS THEFT.

The applications are unlimited.

Retail electronics

University electronics

Manufacturing

Public utilities

Prisons, jails, security facilities

Bank credit card, ATM

Gaming industry

Solar panels

House arrest electronics

Nuclear plants

Military

Museums